Main production introductionThe micro-spray belt making machine is used to make agriculture inline drip irrigation hose .In order to produce this agriculture inline drip irrigation hose making machine, our company makes full market research and assimilates the advanced technology from domestic and overseas. And this machine is the most advanced agriculture inline drip irrigation hose making machine in our company at present.

Contact Now

inlaid cylinder emitter drip irrigating pipe extruder descriptionThis production line is mainly used to prodcue all kinds of drip irrigation pipe, which are widely used in agriculture and construction water supply and drainage and cable laying. This production line is composed of conical (parallel) twin-screw extruder, headpiece, vacuum sizing device, traction machine, cutting machine and stacking device. The extruder and traction machine adopts frequency control. The traction machine can be with two, three, four, six, eight claws.

Contact Now

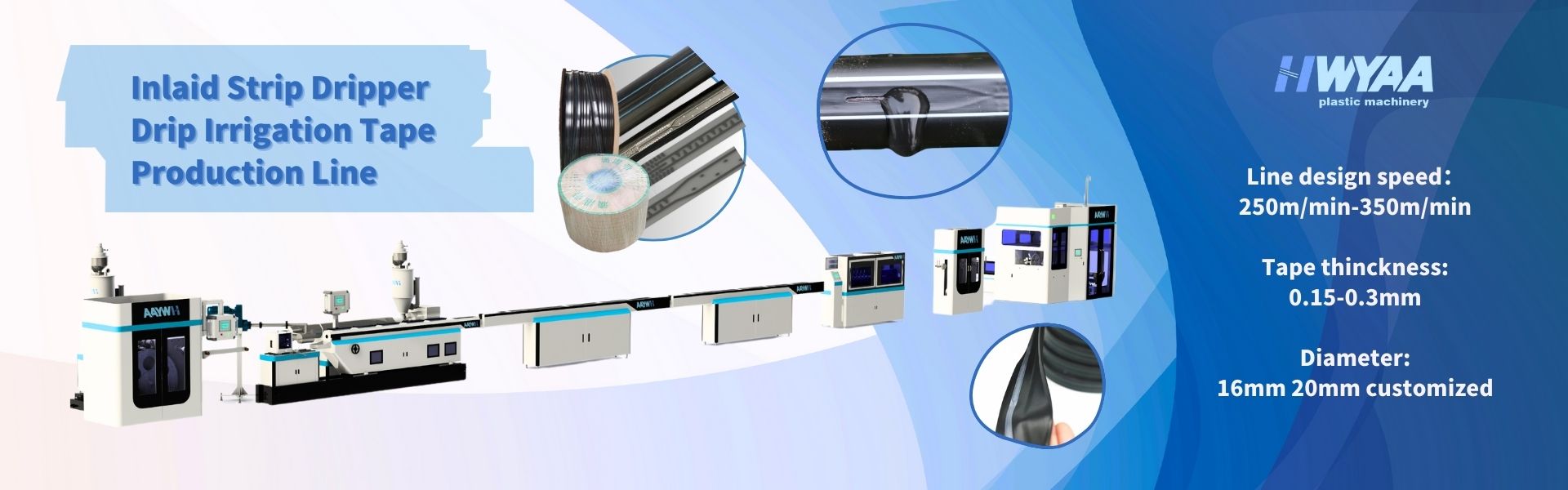

The inlaid flat emitter drip irrigation tape production line is developde by the combination of our own techniques and advanced technologies introduced from foreign countries.The quality of the tape is quite satisfactory.

Contact Now

Short descriptionThe agriculture inline drip irrigation hose extruder machine is used to make agriculture inline irrigation hose tube .In order to produce this agriculture inline irrigation drip hose extruder machine , our company makes full market research and assimilates the advanced technology from domestic and overseas. And this machine is the most advanced agriculture inline irrigation drip hose extruder machine in our company at present.

Contact Now

The inlaid flat drip irrigation pipe machine more effectively manages water demand and maintains the irrigation system.This includes precise water application using wetness frontier detectors; smart irrigation technology to improve irrigation efficiency; technology that uses ultrasonic to clean drip pipes to improve efficiency; and improved irrigation system operation and maintenance through farmland geographic information systems.Application:PIPEPlastic Processed:PECondition:NewScrew Design:Single-screwScrew Speed (rpm):120 rpmShowroom Location:NonePlace of Origin:Shandong, ChinaBrand Name:Hu

Contact Now

The agriculture inline drip irrigation hose extruder machine is used to make agriculture inline irrigation hose tube .In order to produce this agriculture inline irrigation drip hose extruder machine , our company makes full market research and assimilates the advanced technology from domestic and overseas. And this machine is the most advanced agriculture inline irrigation drip hose extruder machine in our company at present.

Contact Now

Convenient and fastThe prepunching outlet water belt adopts a modular design, which is simple and convenient to install.

Contact Now

Short descriptionLabyrinth type drip irrigation equipment is our company draws on the technical advantages of domestic and foreign equipment combined with my unit technology and the development of a new generation of high-speed thin-walled cylinder-type drip irrigation pipe equipment.

Contact Now

Drip irrigation system consists of hose fitted with plastic emitters, that permit water to trickle out at a controlled movement without stopping up. The tubing is laid around the plants and trees to get water into their roots. You can go for pre-punched tubing with emitters already installed, or unperforated tubing, which you have to punch holes in and fix emitters in it.

Contact Now

Drip irrigation tape production line This equipment is mainly composed of a high-speed nozzle machine, a diameter measuring control tube system, a hot press forming machine, a cutter dividing machine, an air intake machine, and a coiling machine. It has the characteristics of simple operation, winding control, high production efficiency and energy saving.

Contact Now

Equipment features:1. Adopts PLC centralized control, stable production process, easy to operate, energy efficient.2. The emitters feeding, screening, transportation, inlaying, pipe output, drilling and rewinding are completed synchronously, high automation.3. The extruded materials are uniformly plasticized, the drip tape surface is smooth and the sizing is accurate.4. The traction machine adopts frequency control, it can be used for a variety of processing requirements. On the track surface has rubber protective layer, can effectively prevent the deformation of drip tape.5.

Contact Now

inlaid cylinder emitter drip irrigating pipe extruder descriptionThis production line is mainly used to prodcue all kinds of drip irrigation pipe, which are widely used in agriculture and construction water supply and drainage and cable laying. This production line is composed of conical (parallel) twin-screw extruder, headpiece, vacuum sizing device, traction machine, cutting machine and stacking device. The extruder and traction machine adopts frequency control. The traction machine can be with two, three, four, six, eight claws.

Contact Now

The inlaid cylindrical emitter drip irrigation pipe production line is developed by the combination of our own techniques andadvanced technologies introduced from foreign countries.Product DescriptionTape Diameter12/16/20mmTape Wall Thickness0.6-1.0mmExtruderSJ-75/33Production Speed50m/min(300mm space)PunchingServo motorExtruding Capacity120KgApplication:PIPEPlastic Processed:PECondition:NewScrew Design:Single-screwScrew Material:38CrMoALAScrew diameter (mm):75 mmScrew L/D Ratio:33:01:00Screw Speed (rpm):90 rpmShowroom Location:India, Mexico, Russia, South Korea, South Africa, UkrainePlace of

Contact Now

Three layers co-extrusion film blowing machine is composed of three single screw extruders, three layer composite co-extrusion die , cooling system, tractor, film coiling device, temperature and electric control system.

Contact Now

As the viscosity of UHMW-PE molten state reaches up to 108Pa*s, liquidity is poor, and melt index is almost zero, so UHMW-PE is hard to be processed by general mechanical processing method.

Contact Now

production line advantages1. It is non-toxic,odorless,anti-aging,lightweight and long serivce life;2.Using high-quality,high tensile-strength PE raw material;3.Holes smooth and evenly,have good resistance to jam;4.According to different crops,selecting diferent holes design,sprary effect is ideal;5.Usingcooperatively with agricultural pumps and low pressure water pipelines use,saving time and saving water;6.Connection with the multi-fountion value,it is free to adjust spraying width,height and area by adjusting the water pressure;7.

Contact Now

With the reduction of water supply and the increasing emphasis on the effective use of resources, irrigation technology is being developed in order to use fewer resources. Although the initial capital cost of the latest equipment and software may be high, its improved efficiency, higher output, and reduced water consumption are invincible.Therefore, reducing the irrigated area cannot solve the problem of water shortage.

Contact Now

product performance and advantagesEasy operationLow maintenanceTake up small areaHigh output capacityLonger life of screw &barrelPP&LD can be processed due to its special screw designAC Invertor & Motor which synchronizes the entire ExtruderLatest technology used to force the melt into the die very effectivelymain technical parametersmodelsj-45/30diameter45mml/d95speed100rpmoutput50kg/hdrive power15heatingdistrict:4power:4central height500/1000emitter max.

Contact Now

main production features1) Dripper and pipe unified,it is convenient for installation and usage,low cost and small investment. 2) The dripper has inherent filtration window,it has good performance of resisting blockage. 3) The machine adopts ladyrinth type passageway,it has certain pressure compensation effect. 4)The space between the dripper can adjust according to the customers' requirements.main production parametersextruder typeSJ-55/28pipe diameter10mmscrew typesingle screwwall thickness0.6mmproduction speed80-200m/minemitter maximum screening speed800pcsemitter inlaid

Contact Now

PRODUCTION LINE DESCRIPTIONSThis production line is mainly used to prodcue all kinds of drip irrigation pipe, which are widely used in agriculture and construction water supply and drainage and cable laying. This production line is composed of conical (parallel) twin-screw extruder, headpiece, vacuum sizing device, traction machine, cutting machine and stacking device. The extruder and traction machine adopts frequency control. The traction machine can be with two, three, four, six, eight claws. This production line is equipped with cutter (saw web or planetary).

Contact Now

Short description1. It is a high-tech enterprise which is specialized in research, manufacture and marketing plastic extrusion lines,plastic production line.2.Our plastic extrusion lines based on Plastic Extruders:Single Screw Extruder,Conical Twin Screw Extruder and Parallel Twin Screw Extruder.3.Our plastic making machine can make many kinds of plastic productions l

Contact Now

1. The goods are packed in accordance with requirements of the manufacturing plant and standards of the Chinese People's Republic.2. Each place be fixed in accordance to the particularities of the goods.

Contact Now

Main production features1) Dripper and pipe unified,it is convenient for installation and usage,low cost and small investment. 2) The dripper has inherent filtration window,it has good performance of resisting blockage. 3) The machine adopts ladyrinth type passageway,it has certain pressure compensation effect. 4)The space between the dripper can adjust according to the customers' requirements. Main production specificationEXTRUDERSJ-30/25SJ-45/30SJ-50/28SJ-55/28SJ-65/25SCREW DIAMETER30MM45MM50MM55MM65MMOUTPUT(KG/H)850609555PRODUCTMICRO-SPRAY BELTMOLDING WAYDOWN-BLOWING

Contact Now

Product Application:This product is mainly used for mine escape pipes, fly ash transportation, marine dredging pipes, etc.Supply Ability:10 Set/Sets per Month UHMWPE Pipe Extrusion Mahcine LinePackaging Details:Usually we use a wrapping film to wrap the machine, then fix the machine with a wire rope, or use wood packaging according to your needs.Technical Parameters:Extruder modelSJ-75/20SJ-90/20SJ-150/20SJ-200/20SJ-240/20Pipe OD range40-89mm90-159mm160-500mm500-800mm800-1200mmMotor power15Kw18.5Kw30Kw55Kw75KwOutput(kg/h)Bracket lengthAccording by clients needTotal power<30<45<65<8

Contact Now